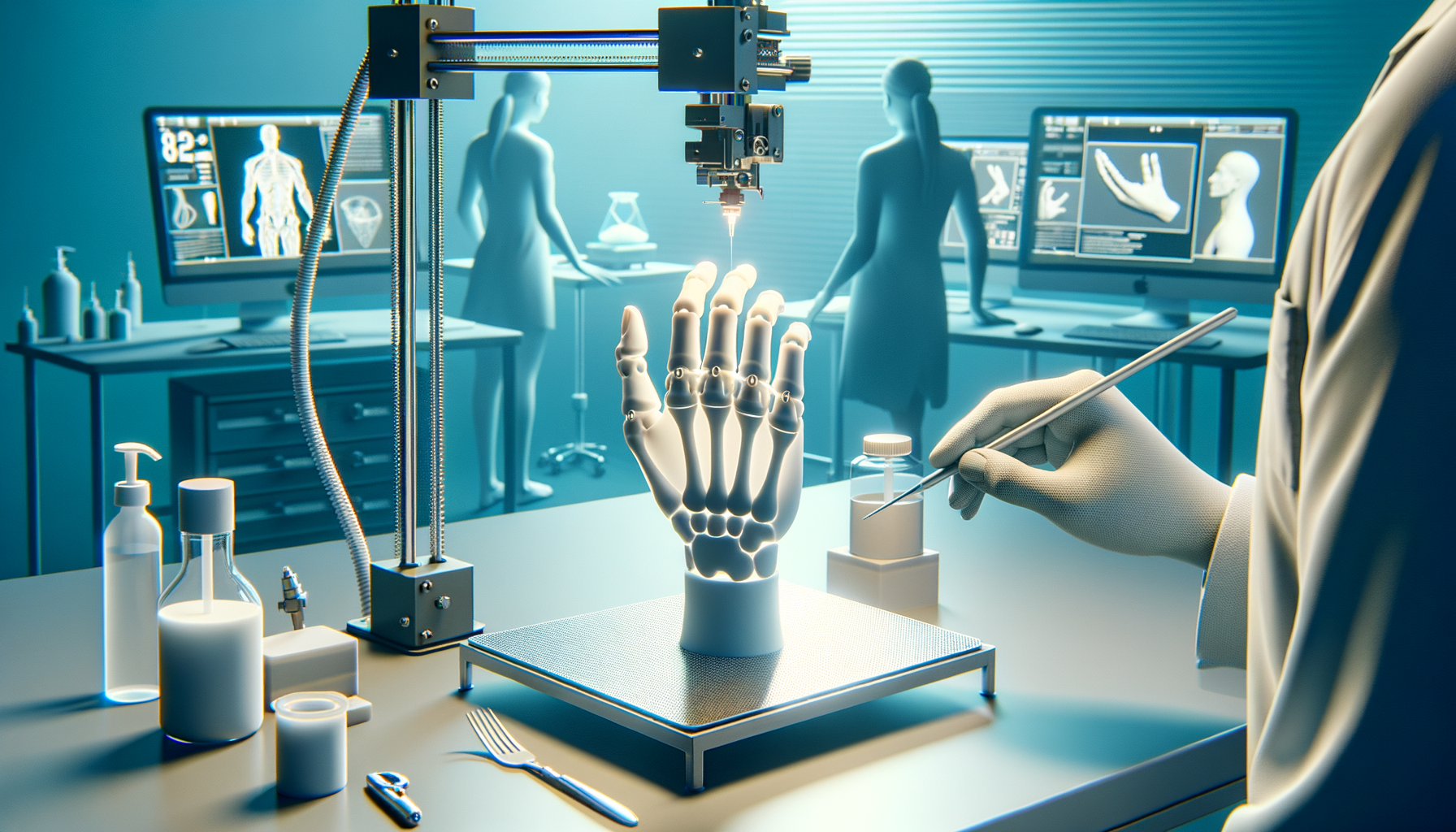

Introduction to 3D Printing in Healthcare

The advent of 3D printing technology has revolutionized various industries, and healthcare is no exception. Particularly, the role of 3D printing in medical prosthetics and assistive devices has been transformative, offering unprecedented opportunities for customization and innovation. This cutting-edge technology, also known as additive manufacturing, allows for the creation of complex structures by layering materials based on digital models. The {KEYWORD} has become a crucial component in developing personalized medical solutions, enhancing patient outcomes, and reducing costs. As the demand for more efficient and tailored healthcare solutions grows, 3D printing stands at the forefront, promising to reshape the future of medical prosthetics and assistive devices.

The integration of 3D printing in healthcare began with the need for rapid prototyping and has since evolved into a vital tool for producing functional medical devices. This technology’s ability to create intricate designs with high precision has made it particularly useful in the field of prosthetics, where the fit and functionality of devices are paramount. The {KEYWORD} not only allows for the production of highly customized prosthetics but also enables the creation of assistive devices that cater to individual needs. As a result, patients can experience improved mobility and comfort, leading to a better quality of life.

Moreover, 3D printing has democratized the production of medical devices, making them more accessible to a broader audience. Traditional manufacturing methods often involve high costs and long lead times, which can be prohibitive for many patients. However, 3D printing offers a cost-effective alternative, allowing for the rapid production of devices at a fraction of the cost. This has significant implications for healthcare systems worldwide, particularly in developing regions where access to affordable medical solutions is limited.

In addition to cost savings, 3D printing also offers environmental benefits. Traditional manufacturing processes often result in significant material waste, whereas additive manufacturing uses only the necessary amount of material, minimizing waste. This not only reduces the environmental impact but also contributes to the sustainability of healthcare practices. As the technology continues to advance, the potential applications of 3D printing in healthcare are vast, promising to revolutionize the industry and improve patient care.

Advancements in Prosthetic Technologies

The field of prosthetics has seen remarkable advancements thanks to 3D printing technology. One of the most significant developments is the ability to create highly customized prosthetic limbs that closely mimic the natural anatomy of the human body. This level of customization is achieved through the use of advanced scanning techniques, which capture the precise measurements and contours of a patient’s residual limb. The {KEYWORD} then uses this data to produce a prosthetic that fits perfectly, enhancing comfort and functionality.

Another notable advancement is the incorporation of lightweight and durable materials in 3D-printed prosthetics. Traditional prosthetic limbs can be cumbersome and uncomfortable, often leading to issues such as skin irritation and limited mobility. However, 3D printing allows for the use of materials like titanium and carbon fiber, which are both strong and lightweight. This results in prosthetics that are not only more comfortable to wear but also more durable, reducing the need for frequent replacements.

In addition to physical improvements, 3D printing has also enabled the integration of smart technologies into prosthetic devices. For example, sensors and microprocessors can be embedded into the prosthetic to provide real-time feedback and enhance functionality. This allows for more natural movement and greater control, significantly improving the user’s experience. The {KEYWORD} has thus paved the way for the development of bionic limbs that offer capabilities beyond those of traditional prosthetics.

Furthermore, 3D printing has facilitated the rapid prototyping and testing of new prosthetic designs. This has accelerated the pace of innovation in the field, allowing for the continuous improvement of prosthetic technologies. Researchers and engineers can quickly iterate on designs, testing new concepts and materials to find the optimal solution for each patient. As a result, the development cycle for new prosthetic devices has been significantly shortened, bringing cutting-edge solutions to patients faster than ever before.

Customization and Accessibility Benefits

One of the most significant benefits of 3D printing in medical prosthetics and assistive devices is the unparalleled level of customization it offers. Every patient is unique, and their prosthetic needs can vary greatly depending on factors such as the level of amputation, lifestyle, and personal preferences. The {KEYWORD} allows for the creation of bespoke devices tailored to the specific requirements of each individual, ensuring a perfect fit and optimal functionality.

This customization extends beyond just the physical fit of the prosthetic. Patients can also choose from a range of aesthetic options, allowing them to personalize their device to reflect their personality and style. This can have a profound impact on a patient’s self-esteem and confidence, as they are no longer limited to generic, one-size-fits-all solutions. The ability to customize both the form and function of prosthetics is a game-changer, offering patients a level of personalization that was previously unattainable.

In addition to customization, 3D printing has also improved the accessibility of medical prosthetics and assistive devices. Traditional manufacturing methods often involve lengthy production times and high costs, which can be prohibitive for many patients. However, 3D printing offers a more efficient and cost-effective alternative, allowing for the rapid production of devices at a fraction of the cost. This has made prosthetics more accessible to a wider audience, particularly in developing regions where access to affordable medical solutions is limited.

The accessibility benefits of 3D printing extend beyond just cost savings. The technology also enables the production of prosthetics in remote or underserved areas, where traditional manufacturing facilities may not be available. Portable 3D printers can be deployed in these regions, allowing for the on-site production of customized prosthetics. This not only reduces the time and cost associated with transporting devices but also ensures that patients receive the care they need in a timely manner. As a result, 3D printing has the potential to bridge the gap in healthcare accessibility, bringing life-changing solutions to those who need them most.

Challenges and Future Prospects in 3D Printing

Despite the numerous benefits of 3D printing in medical prosthetics and assistive devices, there are still several challenges that need to be addressed. One of the primary concerns is the regulatory landscape surrounding the use of 3D-printed medical devices. Ensuring the safety and efficacy of these devices is paramount, and regulatory bodies must establish clear guidelines and standards for their production and use. The {KEYWORD} industry must work closely with regulators to develop a framework that balances innovation with patient safety.

Another challenge is the need for skilled professionals who can design and produce 3D-printed prosthetics. While the technology itself is becoming more accessible, there is still a significant learning curve associated with its use. Training programs and educational initiatives are essential to equip healthcare professionals with the skills and knowledge needed to harness the full potential of 3D printing. As the demand for customized medical solutions grows, so too will the need for skilled practitioners who can deliver these services.

The cost of materials and equipment is another barrier to the widespread adoption of 3D printing in healthcare. While the technology has the potential to reduce overall costs, the initial investment in 3D printers and materials can be significant. However, as the technology continues to evolve and become more mainstream, it is expected that these costs will decrease, making 3D printing an increasingly viable option for healthcare providers.

Looking to the future, the prospects for 3D printing in medical prosthetics and assistive devices are incredibly promising. Advances in materials science and printing techniques are likely to lead to even more sophisticated and functional prosthetics. Additionally, the integration of artificial intelligence and machine learning could further enhance the customization and functionality of these devices. As the technology continues to mature, it has the potential to revolutionize the field of prosthetics, offering patients more personalized and effective solutions than ever before.

Conclusion

In conclusion, the role of 3D printing in medical prosthetics and assistive devices is transformative, offering unprecedented opportunities for customization, accessibility, and innovation. The {KEYWORD} has revolutionized the field of prosthetics, enabling the creation of highly personalized and functional devices that enhance patient outcomes. While there are challenges to overcome, such as regulatory hurdles and the need for skilled professionals, the future prospects for 3D printing in healthcare are incredibly promising. As the technology continues to advance, it has the potential to reshape the industry, bringing life-changing solutions to patients worldwide and improving the overall quality of care.