The realm of 3D printing, also known as additive manufacturing, has evolved rapidly over the past decade, revolutionizing industries from manufacturing to healthcare. By 2025, the technology will have advanced even further, enabling new capabilities and applications that were once thought impossible. Innovations in materials, speed, precision, and even the integration of artificial intelligence (AI) are all contributing to an exciting new era for 3D printing.

As we look ahead, it’s clear that 3D printing will continue to reshape industries by providing more cost-effective, efficient, and sustainable solutions. In this article, we’ll explore the transformative technologies and key trends expected to define the future of 3D printing, providing a comprehensive look at the innovations and advancements that will be pivotal in the coming years.

Emerging Technologies Shaping 3D Printing in 2025

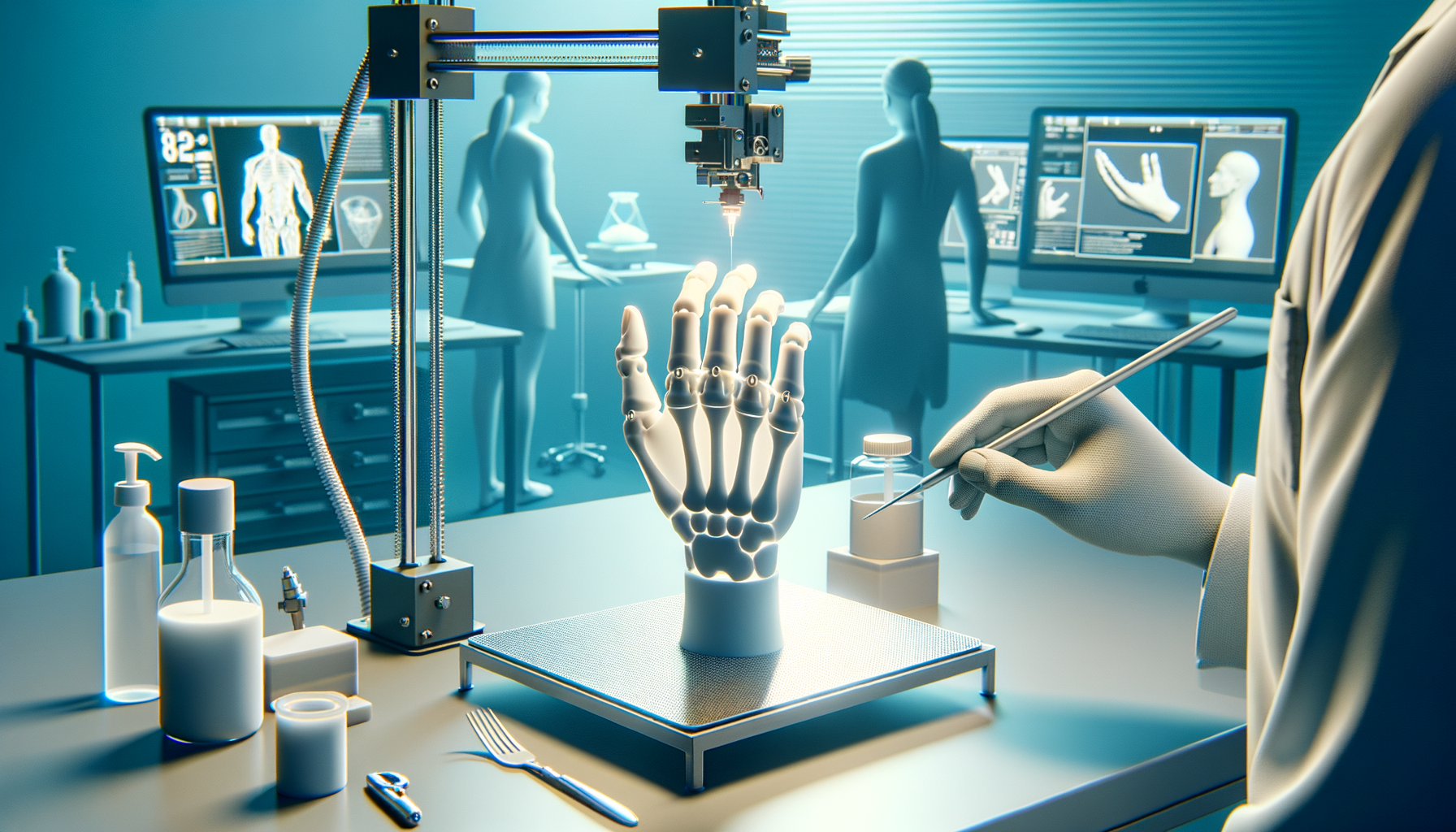

1. Bioprinting: The Next Frontier in Medicine

One of the most exciting developments in the field of 3D printing is bioprinting, which involves printing with living cells to create biological tissues and organs. By 2025, this technology could make significant strides, particularly in the area of organ transplantation. Currently, there is a global shortage of organs for transplantation, with many patients waiting for years to receive a suitable match. Bioprinting could dramatically reduce this waiting time by creating fully functional organs using a patient’s own cells, which would minimize the risk of organ rejection.

Researchers are already developing bio-inks, which are made from natural materials and are designed to promote cell growth and viability. By printing tissues with specific structures and cell types, scientists aim to create organs that function similarly to natural ones, providing a long-term solution to the organ donation crisis.

While fully functional organ printing is still in the research phase, significant progress is being made. By 2025, we may witness the first successful trials of printed tissues or organs being used in medical treatments. This could change the landscape of healthcare, saving lives and reducing the need for organ donors.

Key Benefits:

- Reduced organ transplant waiting times.

- Lower risk of organ rejection by using the patient’s own cells.

- Potential for customized medical solutions based on patient-specific needs.

2. Artificial Intelligence (AI) in 3D Printing

The integration of artificial intelligence (AI) into 3D printing is set to revolutionize the way printers operate. By harnessing AI and machine learning algorithms, 3D printers can become more efficient, accurate, and capable of handling complex tasks with minimal human intervention.

AI can analyze data from previous prints to optimize various parameters such as temperature, speed, and material usage, ensuring that prints are not only accurate but also cost-effective. Additionally, AI-driven systems can predict potential issues or failures during the printing process, allowing for real-time adjustments. This reduces the likelihood of errors, enhances consistency, and ultimately lowers the amount of wasted material.

Moreover, AI can facilitate design optimization, using algorithms to create more efficient and functional designs that reduce material waste and improve performance. In industries like aerospace, automotive, and consumer products, where precision is critical, AI integration will play a vital role in maximizing the capabilities of 3D printing.

Key Benefits:

- Improved accuracy and quality control.

- Real-time failure prediction and troubleshooting.

- Optimized material usage, reducing costs and waste.

3. Multi-Material Printing: Versatility and Complex Designs

Multi-material 3D printing is another game-changer that is set to dominate the industry by 2025. Traditionally, most 3D printers have used a single material for printing, but advancements in multi-material printing allow for the simultaneous use of different materials within a single print job. This capability enables the production of complex assemblies without the need for post-processing assembly steps.

For example, printers can combine rigid materials with flexible ones, or incorporate materials with varying properties like electrical conductivity or heat resistance. This is particularly valuable in industries like aerospace, where complex parts with multiple functional requirements can be created in one step. Similarly, in consumer goods, this technology allows for the creation of customized products that combine multiple textures and functionalities in a single design.

Multi-material printing will not only increase efficiency in manufacturing but also open up new design possibilities that were previously unattainable. As we move towards 2025, the ability to print varying materials in one layer adds unprecedented versatility to product design and functionality.

Key Benefits:

- Complex geometries and designs without the need for assembly.

- Customization of products with different material properties.

- Time-saving and cost-effective production processes.

Key Trends and Innovations to Monitor in 2025

1. Sustainability in 3D Printing

As environmental concerns grow, sustainability has become a key focus in the 3D printing industry. By 2025, we can expect to see a significant rise in the use of eco-friendly materials, such as biodegradable filaments and recycled plastics. This will help reduce the carbon footprint associated with traditional manufacturing processes.

One particularly exciting trend is the development of recyclable filaments, which can be melted down and re-extruded into new prints. This aligns with global sustainability goals and encourages the circular economy in manufacturing. Companies are also looking at ways to reduce waste during the printing process, which could lower material costs and make production more efficient.

As the push for sustainability intensifies, 3D printing will be at the forefront of providing environmentally friendly solutions. The bio-based filaments of 2025 will not only meet the rising demand for sustainable production but will also provide high-quality materials suitable for various industries.

Key Benefits:

- Reduction in manufacturing waste.

- Environmentally friendly materials and practices.

- Cost-effective solutions for companies aiming to go green.

2. On-Demand Manufacturing

The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting many industries to adopt more resilient and flexible production models. By 2025, on-demand manufacturing powered by 3D printing will become more widespread, allowing businesses to produce components and products as needed.

This approach minimizes the need for large inventories and long lead times, ensuring that companies can quickly respond to market demands or disruptions. On-demand manufacturing will be particularly useful in sectors like automotive, aerospace, and medical equipment, where the ability to create spare parts or customized components on demand is invaluable.

With 3D printing, businesses will be able to produce parts locally, reducing transportation costs and lead times. This will enable industries to create tailored solutions at a fraction of the cost and time compared to traditional methods.

Key Benefits:

- Reduced inventory costs.

- Faster production times and better responsiveness to market demands.

- Local production reducing shipping costs and environmental impact.

3. Democratization of 3D Printing

The democratization of 3D printing is another key trend to watch in the coming years. As the cost of 3D printers continues to decrease and user-friendly software becomes more prevalent, small businesses and individual creators are gaining access to advanced 3D printing technologies that were once reserved for large corporations.

By 2025, platforms that enable cloud-based 3D printing services will likely emerge, allowing individuals and businesses to upload their designs and have them printed and shipped directly to them. This will open the door for greater creativity and innovation, as more people will be able to experiment with 3D printing without needing to invest heavily in expensive equipment.

This democratization is likely to fuel entrepreneurial growth and the development of niche markets, as 3D printing becomes more accessible to the masses.

Key Benefits:

- Increased accessibility for small businesses and individuals.

- Lower entry costs for entrepreneurs and startups.

- Fostering innovation and creativity across industries.

Conclusion

The future of 3D printing is filled with immense possibilities, with groundbreaking advancements in bioprinting, AI integration, and multi-material printing paving the way for new applications and innovations. By 2025, the industry will continue to evolve, focusing on sustainability, on-demand manufacturing, and making 3D printing technology more accessible to a broader audience.

As these technologies and trends unfold, industries across the globe will be transformed by the ability to create highly customized, durable, and sustainable products in ways never seen before. For businesses and creators, staying informed about the latest developments in 3D printing will be essential in positioning themselves to take full advantage of the opportunities on the horizon.

Call to Action

Ready to explore the future of 3D printing? Stay ahead of the curve by embracing the latest trends and innovations shaping the industry in 2025. Start your next project today with the cutting-edge potential of additive manufacturing!