Introduction to 3D Printing in Fashion

In recent years, the fashion industry has been undergoing a significant transformation, driven by technological advancements. One of the most groundbreaking innovations is 3D printing, which is revolutionizing how fashion is designed, produced, and consumed. As we step into 2025, 3D printing in fashion is no longer a futuristic concept but a tangible reality reshaping the industry. This technology offers designers unprecedented creative freedom, allowing them to push the boundaries of traditional fashion design and production. By integrating 3D printing into their processes, fashion designers can create intricate designs, reduce waste, and customize garments like never before.

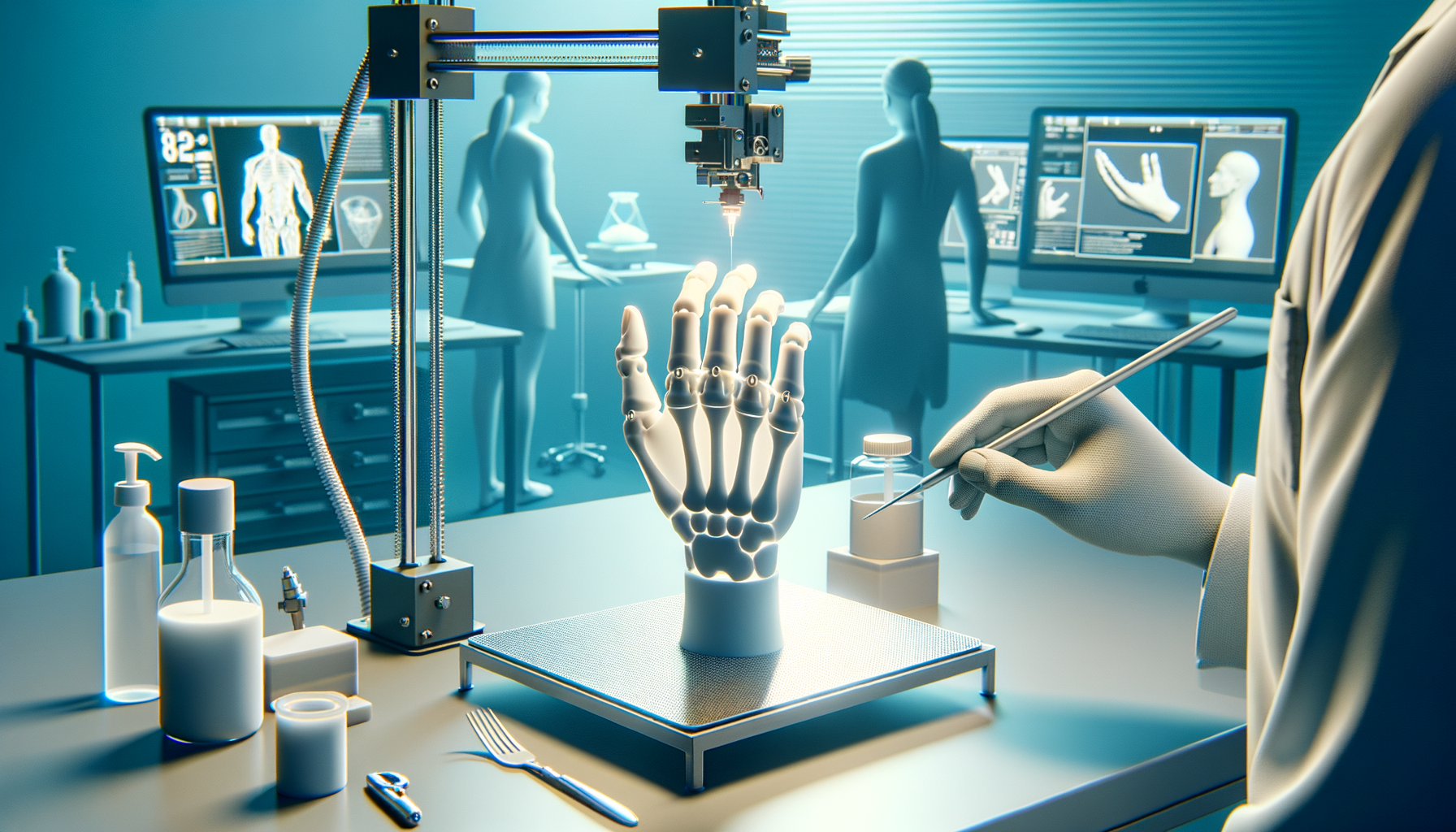

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by layering materials based on digital models. In the fashion industry, this technology is being used to produce everything from clothing and accessories to footwear. The ability to print garments directly from a digital file means that designers can experiment with complex geometries and structures that would be impossible or too costly to achieve with conventional methods. This innovation is not only transforming the aesthetics of fashion but also its functionality, as designers can now incorporate unique features into their creations.

The adoption of 3D printing in fashion is driven by the industry’s need for sustainability and efficiency. Traditional fashion production methods are often resource-intensive and generate significant waste. In contrast, 3D printing allows for on-demand production, reducing the need for large inventories and minimizing fabric waste. Additionally, the technology enables the use of sustainable materials, further aligning with the industry’s growing commitment to environmental responsibility. As consumers become more conscious of the environmental impact of their purchases, 3D printing offers a viable solution for creating eco-friendly fashion.

Moreover, 3D printing is democratizing fashion by making it more accessible to independent designers and small businesses. The cost of entry into the fashion industry has traditionally been high, with significant investments required for materials, manufacturing, and distribution. However, 3D printing reduces these barriers by allowing designers to produce their creations in-house, without the need for large-scale manufacturing facilities. This shift is empowering a new generation of designers to bring their visions to life and compete in the global fashion market.

Benefits of 3D Printing for Designers

One of the most significant benefits of 3D printing for fashion designers is the ability to create highly customized and personalized garments. In a world where consumers increasingly seek unique and individualized products, 3D printing offers designers the tools to meet these demands. By using digital design software, designers can easily modify patterns and create bespoke pieces tailored to the specific measurements and preferences of their clients. This level of customization was previously unattainable with traditional manufacturing methods, which often required mass production to be cost-effective.

In addition to customization, 3D printing provides designers with unparalleled creative freedom. The technology allows for the creation of complex structures and intricate details that would be difficult or impossible to achieve with conventional techniques. Designers can experiment with new forms, textures, and patterns, pushing the boundaries of what is possible in fashion design. This creative freedom is fostering innovation and leading to the development of avant-garde fashion pieces that challenge traditional aesthetics and redefine the concept of clothing.

Another advantage of 3D printing is its potential to streamline the design and production process. Traditional fashion production involves multiple stages, from sketching and pattern-making to cutting and sewing, each of which can be time-consuming and costly. In contrast, 3D printing simplifies this process by allowing designers to go directly from a digital model to a finished product. This efficiency not only reduces production time but also lowers costs, making it easier for designers to bring their creations to market quickly and affordably.

Furthermore, 3D printing is enabling designers to experiment with new materials and techniques. The technology supports a wide range of materials, from traditional plastics and metals to innovative bio-based and recycled materials. This versatility allows designers to explore sustainable alternatives and incorporate them into their collections. As the fashion industry continues to prioritize sustainability, the ability to work with eco-friendly materials is becoming increasingly important. 3D printing offers designers the opportunity to lead the way in sustainable fashion innovation.

Innovations in 3D Printed Fashion Materials

The evolution of 3D printing in fashion is closely tied to advancements in materials science. As the technology has progressed, so too have the materials available for 3D printing, leading to exciting innovations in the fashion industry. One of the most notable developments is the creation of flexible and durable materials that mimic the properties of traditional fabrics. These materials allow designers to produce garments that not only look but also feel like conventional clothing, offering the comfort and wearability that consumers expect.

In addition to mimicking traditional fabrics, 3D printing is enabling the development of entirely new materials with unique properties. For example, some designers are experimenting with materials that change color or texture in response to environmental stimuli, such as temperature or light. These smart materials open up new possibilities for interactive and adaptive fashion, where garments can respond to the wearer’s surroundings or preferences. This innovation is paving the way for a new era of fashion that is both functional and expressive.

Sustainability is a key focus in the development of 3D printed fashion materials. Researchers and designers are exploring the use of bio-based and recycled materials to create eco-friendly fashion. For instance, some are experimenting with bioplastics derived from renewable resources, such as corn starch or algae, which can be used to produce biodegradable garments. Others are using recycled plastics, such as PET bottles, to create new textiles, reducing waste and promoting circular fashion. These sustainable materials align with the industry’s commitment to reducing its environmental impact and offer consumers more responsible fashion choices.

Moreover, 3D printing is facilitating the integration of technology into fashion through the use of conductive and electronic materials. Designers are incorporating sensors, LEDs, and other electronic components into their 3D printed garments, creating wearable technology that combines fashion with functionality. This convergence of fashion and technology is leading to the development of smart clothing that can monitor health, track fitness, or even charge electronic devices. As the demand for wearable technology grows, 3D printing is playing a crucial role in bringing these innovative concepts to life.

Challenges and Future Prospects in 3D Fashion

Despite the many benefits and innovations associated with 3D printing in fashion, the technology also presents several challenges that need to be addressed. One of the primary obstacles is the high cost of 3D printing equipment and materials, which can be prohibitive for small designers and startups. While the technology has become more accessible in recent years, significant investments are still required to adopt 3D printing on a large scale. As the technology continues to evolve, reducing costs and increasing accessibility will be crucial for widespread adoption in the fashion industry.

Another challenge is the limited range of materials currently available for 3D printing. While there have been significant advancements in material science, the options for 3D printed fashion are still relatively limited compared to traditional textiles. Developing new materials that offer the same comfort, durability, and aesthetic appeal as conventional fabrics is essential for the technology to gain broader acceptance among designers and consumers. Continued research and collaboration between material scientists and fashion designers will be key to overcoming this hurdle.

The integration of 3D printing into existing fashion production processes also presents logistical challenges. Many fashion brands have established supply chains and manufacturing practices that are not easily adaptable to 3D printing. Transitioning to this new technology requires significant changes in production workflows and may necessitate retraining staff or hiring new talent with expertise in 3D design and printing. Overcoming these logistical challenges will require a concerted effort from industry stakeholders to embrace and invest in the potential of 3D printing.

Looking ahead, the future prospects for 3D printing in fashion are promising. As the technology continues to advance, it is likely to become an integral part of the fashion industry, offering new opportunities for creativity, sustainability, and innovation. The ongoing development of new materials and printing techniques will expand the possibilities for 3D printed fashion, enabling designers to create garments that are not only visually stunning but also environmentally responsible. As consumers increasingly demand personalized and sustainable fashion, 3D printing is poised to play a pivotal role in shaping the future of the industry.

Conclusion

In conclusion, 3D printing is transforming the fashion industry in 2025 by offering designers unprecedented creative freedom, enabling sustainable practices, and democratizing access to fashion design. The technology’s ability to produce customized, intricate designs and experiment with innovative materials is reshaping the way fashion is conceived and produced. While challenges remain, such as high costs and limited material options, the future prospects for 3D printing in fashion are bright. As the industry continues to evolve, 3D printing is set to play a crucial role in driving innovation and sustainability, ultimately redefining the fashion landscape for designers and consumers alike.