1. Introduction to 3D Printing and Its Environmental Implications

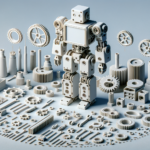

3D printing, also known as additive manufacturing, has revolutionized the way we create and manufacture objects. From intricate jewelry to entire houses, 3D printing technology has the potential to transform industries and our everyday lives. However, as with any technological advancement, it’s crucial to consider its environmental impact. As we explore the environmental impact of 3D printing in 2025, we must understand how this technology works, the materials it uses, and the energy it consumes.

3D printing involves creating a three-dimensional object from a digital file. The process involves layering materials until the desired object is formed. This technology has been praised for its efficiency and precision, but the environmental implications are a growing concern. The materials used in 3D printing, the energy consumption during the process, and the waste generated are all factors that contribute to its environmental footprint.

The environmental impact of 3D printing is a complex issue. On one hand, 3D printing has the potential to reduce waste and energy consumption by enabling localized production and reducing the need for transportation. On the other hand, the materials used in 3D printing can be harmful to the environment, and the energy consumption during the printing process can be significant.

As we continue to adopt and expand the use of 3D printing technology, it’s essential to understand and mitigate its environmental impact. This article will explore the current state of 3D printing in 2025, the environmental impact of the materials used, the energy consumption during the printing process, waste management, and recycling in 3D printing, and future perspectives on reducing the environmental footprint of 3D printing.

2. The Current State of 3D Printing in 2025

As of 2025, 3D printing has become more prevalent in various industries, including healthcare, automotive, aerospace, and construction. The technology has advanced significantly, with improvements in speed, accuracy, and the range of materials that can be used. Despite these advancements, the environmental impact of 3D printing remains a concern.

The materials used in 3D printing have diversified, with a range of plastics, metals, ceramics, and even biological materials now available. However, many of these materials are not biodegradable and can have a significant environmental impact if not properly managed. Additionally, the energy consumption during the 3D printing process can be substantial, particularly for large-scale industrial printing.

Waste management and recycling in 3D printing are also significant issues. While 3D printing has the potential to reduce waste by only using the necessary materials, the reality is that a significant amount of waste is generated during the printing process. This waste needs to be properly managed and recycled to minimize its environmental impact.

Despite these challenges, there are promising developments in reducing the environmental footprint of 3D printing. Innovations in materials, energy efficiency, and waste management are all being explored to make 3D printing more sustainable.

3. Environmental Impact of 3D Printing Materials

The materials used in 3D printing have a significant impact on its environmental footprint. Many 3D printers use plastic-based materials, which can be harmful to the environment. These plastics are often non-biodegradable and can take hundreds of years to decompose. Additionally, the production of these plastics can contribute to greenhouse gas emissions and other forms of pollution.

Metals are another common material used in 3D printing, particularly in industrial applications. While metals can be recycled, the process of mining and refining metals is energy-intensive and can have a significant environmental impact. Additionally, some metals used in 3D printing, such as titanium and cobalt, are scarce and their extraction can have negative environmental and social impacts.

There are, however, promising developments in the use of more sustainable materials in 3D printing. Biodegradable plastics, made from renewable resources like corn starch or sugar cane, are becoming more common. Additionally, research is being conducted into the use of recycled materials in 3D printing, which could significantly reduce its environmental impact.

4. Energy Consumption in 3D Printing Processes

Energy consumption is another significant factor in the environmental impact of 3D printing. The amount of energy consumed during the 3D printing process can vary widely depending on the type of printer, the material used, and the complexity of the object being printed. However, in general, 3D printing is a relatively energy-intensive process, particularly for metal-based printing.

One of the reasons for the high energy consumption of 3D printing is the need to heat materials to high temperatures. This is particularly true for metal-based printing, where materials need to be heated to melting point. Additionally, the layer-by-layer nature of 3D printing means that the process can be slow and require a significant amount of energy.

However, there are ways to reduce the energy consumption of 3D printing. Improvements in printer efficiency, the use of renewable energy sources, and the development of new printing techniques can all help to reduce the energy footprint of 3D printing. Additionally, localized production through 3D printing can reduce the need for transportation, which can also help to reduce overall energy consumption.

5. Waste Management and Recycling in 3D Printing

Waste management and recycling are critical aspects of reducing the environmental impact of 3D printing. Despite the potential for 3D printing to reduce waste by only using the necessary materials, the reality is that a significant amount of waste is generated during the printing process. This waste can include unused materials, support structures, and failed prints.

Proper waste management is essential to minimize the environmental impact of this waste. This can include recycling unused materials, composting biodegradable waste, and properly disposing of hazardous waste. Additionally, the development of new printing techniques that reduce the need for support structures can help to reduce waste.

Recycling is another important aspect of waste management in 3D printing. This can include recycling unused materials, as well as recycling the end product once it has reached the end of its life. There are challenges to recycling in 3D printing, including the need for separation and cleaning of materials, but advancements are being made in this area.

6. Future Perspectives: Reducing the Environmental Footprint of 3D Printing

Looking to the future, there are several ways in which the environmental footprint of 3D printing could be reduced. One of the most promising is the development of more sustainable materials. This could include biodegradable plastics, recycled materials, and even materials derived from waste products.

Energy efficiency is another area where significant improvements could be made. This could include improvements in printer efficiency, the use of renewable energy sources, and the development of new printing techniques that require less energy. Additionally, localized production through 3D printing could reduce the need for transportation, further reducing energy consumption.

Waste management and recycling will also be critical in reducing the environmental impact of 3D printing. This could include improved waste management practices, the development of new printing techniques that reduce waste, and advancements in recycling technology.

In conclusion, while 3D printing has significant potential to transform industries and our everyday lives, it’s crucial that we understand and mitigate its environmental impact. By exploring and addressing the environmental impact of 3D printing materials, energy consumption, and waste management, we can ensure that this technology is used in a way that is sustainable and beneficial for our planet.