Introduction to 3D Printing in Consumer Goods

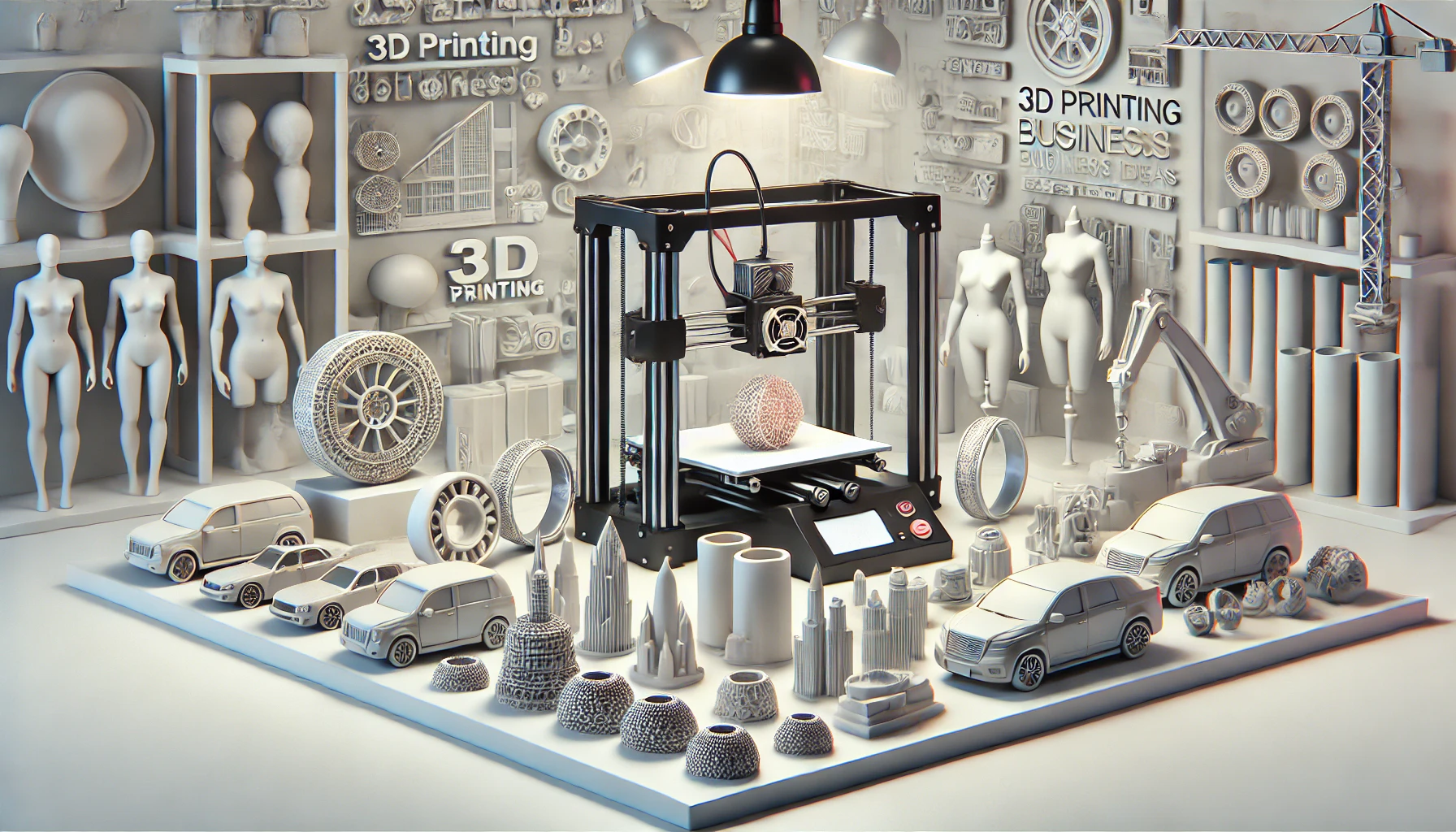

In recent years, the advent of 3D printing has revolutionized the landscape of consumer goods, ushering in a new era of customization and personalization. This transformative technology, also known as additive manufacturing, allows for the creation of three-dimensional objects from digital files, offering unprecedented flexibility and innovation in product design and manufacturing. As consumers increasingly seek products that reflect their unique preferences and lifestyles, 3D printing has emerged as a powerful tool to meet these demands. By enabling the production of customized goods at scale, 3D printing is reshaping the consumer goods industry, offering both opportunities and challenges for businesses and consumers alike.

The impact of 3D printing on customization in consumer goods is profound, as it allows for the creation of tailor-made products that cater to individual tastes and requirements. From personalized fashion items and bespoke jewelry to custom-fit footwear and unique home decor, 3D printing is enabling consumers to express their individuality like never before. This shift towards personalization is not only enhancing consumer satisfaction but also driving innovation and competition in the market. As businesses strive to meet the growing demand for customized products, they are increasingly turning to 3D printing as a viable solution.

Moreover, the integration of 3D printing into the consumer goods sector is fostering a more sustainable and efficient production process. By reducing material waste and minimizing the need for large inventories, 3D printing is helping businesses to lower their environmental footprint while also reducing costs. This is particularly important in today’s eco-conscious market, where consumers are increasingly prioritizing sustainability in their purchasing decisions. As a result, 3D printing is not only transforming the way products are made but also how they are consumed.

As we delve deeper into the impact of 3D printing on customization in consumer goods, it is essential to explore the evolution of this technology and its implications for the industry. From its early beginnings to its current applications, 3D printing has come a long way, and its potential for further growth and innovation is immense. In the following sections, we will examine the evolution of customization through 3D printing, the benefits it offers for personalized products, and the challenges businesses face in implementing these solutions.

Evolution of Customization Through 3D Printing

The journey of 3D printing in the realm of consumer goods began with its initial development in the 1980s, primarily for industrial applications. However, as the technology matured and became more accessible, it gradually found its way into the consumer market. The early 2000s marked a significant turning point, as advancements in 3D printing technology made it feasible for businesses to offer customized products to consumers. This shift was driven by the growing demand for personalization, as consumers sought products that reflected their unique tastes and preferences.

One of the most notable milestones in the evolution of 3D printing for customization was the introduction of affordable desktop 3D printers. These devices democratized access to 3D printing technology, enabling small businesses and individual consumers to create customized products from the comfort of their own homes. This development not only expanded the possibilities for personalization but also empowered consumers to become creators, blurring the lines between producers and consumers. As a result, the concept of mass customization gained traction, allowing businesses to offer a wide range of personalized products without the need for large-scale production facilities.

As 3D printing technology continued to evolve, so too did the range of materials and techniques available for creating customized consumer goods. From plastics and metals to ceramics and even bio-materials, the diversity of materials used in 3D printing has expanded significantly, allowing for greater creativity and innovation in product design. This has enabled businesses to offer a wider variety of customized products, catering to different consumer needs and preferences. Furthermore, advancements in 3D printing software have made it easier for businesses to design and produce complex, intricate products, further enhancing the potential for customization.

Today, 3D printing is at the forefront of the customization revolution, with businesses across various industries leveraging this technology to offer personalized products. From fashion and footwear to electronics and home goods, the applications of 3D printing in consumer goods are vast and varied. As the technology continues to advance, it is likely that we will see even more innovative and creative uses of 3D printing for customization, further transforming the consumer goods industry.

Benefits of 3D Printing for Personalized Products

One of the primary benefits of 3D printing for personalized products is the ability to create tailor-made solutions that cater to individual consumer needs. Unlike traditional manufacturing methods, which often require large production runs to be cost-effective, 3D printing allows for the creation of one-of-a-kind products without the need for expensive tooling or molds. This flexibility enables businesses to offer a wide range of customized options, from personalized jewelry and fashion accessories to custom-fit footwear and ergonomic furniture. By meeting the unique preferences and requirements of consumers, businesses can enhance customer satisfaction and loyalty, ultimately driving sales and growth.

In addition to offering greater customization, 3D printing also provides significant cost and time savings for businesses. By eliminating the need for large inventories and reducing material waste, 3D printing can help businesses lower their production costs and improve their bottom line. Furthermore, the ability to quickly produce prototypes and iterate on designs allows businesses to bring new products to market faster, giving them a competitive edge in today’s fast-paced consumer goods industry. This agility is particularly important in industries where trends and consumer preferences are constantly evolving, as it enables businesses to respond quickly to changing demands.

Another key benefit of 3D printing for personalized products is its potential for sustainability. Traditional manufacturing processes often result in significant material waste and energy consumption, contributing to environmental degradation. In contrast, 3D printing is an additive process, meaning that it only uses the material necessary to create the final product, minimizing waste and reducing the environmental impact. Additionally, 3D printing allows for localized production, reducing the need for long-distance transportation and further lowering the carbon footprint. As consumers become increasingly conscious of their environmental impact, the sustainability benefits of 3D printing are becoming a key selling point for businesses.

Finally, 3D printing offers the potential for greater innovation and creativity in product design. With the ability to create complex, intricate shapes and structures that would be difficult or impossible to achieve with traditional manufacturing methods, 3D printing opens up new possibilities for product design and functionality. This has led to the development of innovative products that not only meet consumer needs but also push the boundaries of what is possible in the consumer goods industry. As businesses continue to explore the potential of 3D printing for customization, we can expect to see even more exciting and groundbreaking products in the future.

Challenges in Implementing 3D Printing Solutions

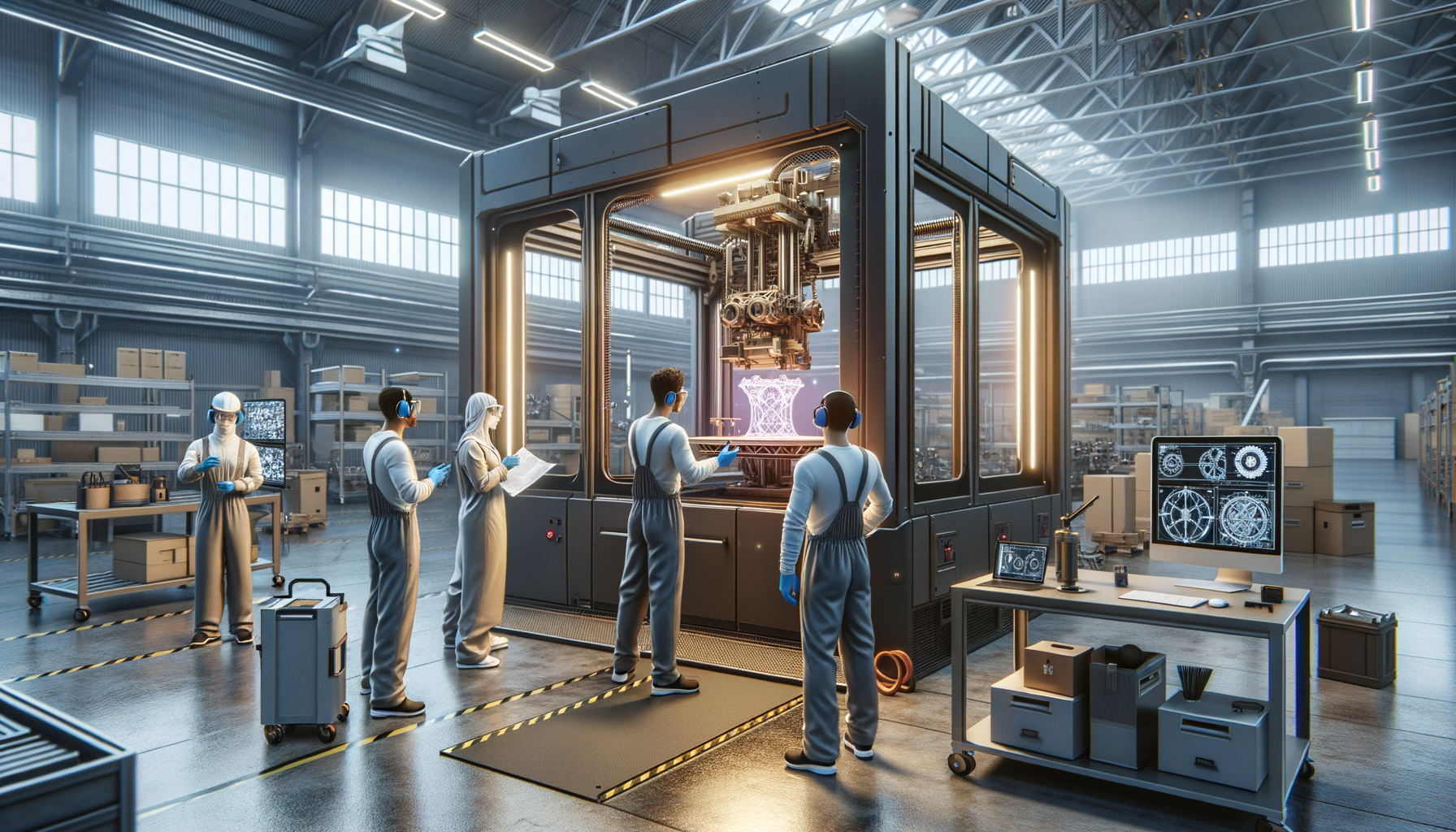

Despite the numerous benefits of 3D printing for customization in consumer goods, there are also several challenges that businesses must overcome to successfully implement this technology. One of the primary challenges is the high initial cost of 3D printing equipment and materials. While the cost of 3D printers has decreased significantly in recent years, high-quality industrial-grade printers and specialized materials can still be expensive, making it difficult for small businesses to invest in this technology. Additionally, the cost of training employees to operate and maintain 3D printing equipment can also be a barrier for businesses looking to adopt this technology.

Another challenge in implementing 3D printing solutions is the complexity of the design and production process. Creating customized products with 3D printing requires a high level of expertise in design software and 3D modeling, which can be a steep learning curve for businesses that are new to this technology. Furthermore, the production process can be time-consuming, particularly for complex or intricate designs, which can limit the scalability of 3D printing for mass customization. Businesses must carefully consider these factors when deciding whether to invest in 3D printing for customization.

Quality control is another significant challenge in the implementation of 3D printing solutions. Ensuring the consistency and quality of 3D printed products can be difficult, particularly when using a wide range of materials and techniques. Variations in material properties, printer calibration, and environmental conditions can all impact the final product, leading to inconsistencies and defects. Businesses must invest in rigorous quality control processes and testing to ensure that their 3D printed products meet the necessary standards and specifications.

Finally, there are also regulatory and legal challenges associated with 3D printing for customization. As the technology continues to evolve, there is a lack of clear regulations and standards governing the use of 3D printing in consumer goods, which can create uncertainty for businesses. Additionally, issues related to intellectual property and copyright infringement can arise when creating customized products, particularly when using digital files or designs created by third parties. Businesses must navigate these complex legal and regulatory landscapes to successfully implement 3D printing solutions for customization.

Conclusion

In conclusion, the impact of 3D printing on customization in consumer goods is both profound and far-reaching. This transformative technology has opened up new possibilities for personalization, enabling businesses to offer tailor-made products that cater to individual consumer needs and preferences. By providing significant cost and time savings, enhancing sustainability, and fostering innovation, 3D printing is reshaping the consumer goods industry and driving a new era of customization. However, businesses must also navigate the challenges associated with implementing 3D printing solutions, including high initial costs, complexity in design and production, quality control, and regulatory and legal issues.

As 3D printing technology continues to advance, it is likely that we will see even more innovative and creative uses of this technology for customization in the consumer goods sector. By embracing the potential of 3D printing and overcoming the associated challenges, businesses can not only meet the growing demand for personalized products but also gain a competitive edge in the market. Ultimately, the future of 3D printing in consumer goods holds immense potential, offering exciting opportunities for both businesses and consumers alike.