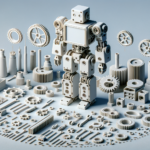

Introduction to 3D Printing in Manufacturing

In recent years, 3D printing, also known as additive manufacturing, has emerged as a transformative force in the manufacturing industry. This innovative technology, which involves creating three-dimensional objects from digital files, is revolutionizing how products are designed, prototyped, and produced. As industries across the globe seek to adopt more sustainable practices, the role of 3D printing in sustainable manufacturing has become increasingly significant. By minimizing waste, reducing energy consumption, and enabling localized production, 3D printing offers a promising path toward more environmentally friendly manufacturing processes. This article explores the various ways in which 3D printing contributes to sustainable manufacturing, highlighting its environmental benefits, waste reduction capabilities, and energy efficiency.

Environmental Benefits of 3D Printing

One of the most compelling environmental benefits of 3D printing is its potential to significantly reduce material waste. Traditional manufacturing methods, such as subtractive manufacturing, often involve cutting away excess material from a larger block, leading to substantial waste. In contrast, 3D printing builds objects layer by layer, using only the material necessary to create the final product. This additive approach not only conserves resources but also reduces the environmental impact associated with waste disposal.

Moreover, 3D printing allows for the use of a wide range of sustainable materials, including biodegradable plastics and recycled composites. These materials can be sourced from renewable resources, further enhancing the environmental benefits of additive manufacturing. By incorporating eco-friendly materials into the production process, manufacturers can reduce their reliance on non-renewable resources and decrease their carbon footprint.

Another environmental advantage of 3D printing is its ability to facilitate localized production. By enabling on-demand manufacturing, 3D printing reduces the need for large-scale transportation of goods, which is a major contributor to greenhouse gas emissions. Localized production not only shortens supply chains but also supports local economies, creating a more sustainable and resilient manufacturing ecosystem.

Furthermore, 3D printing can contribute to the development of more efficient and sustainable product designs. The technology allows for complex geometries and lightweight structures that are often difficult or impossible to achieve with traditional manufacturing methods. These innovative designs can lead to products that require less material and energy to produce, use, and transport, ultimately reducing their overall environmental impact.

Reducing Waste with Additive Manufacturing

A key advantage of 3D printing in sustainable manufacturing is its ability to minimize waste through precise material usage. Unlike traditional manufacturing processes that often result in excess material being discarded, 3D printing uses only the material necessary to construct the final product. This precision not only conserves resources but also reduces the environmental burden associated with waste management and disposal.

In industries such as aerospace and automotive, where material costs and waste are significant concerns, 3D printing offers a sustainable alternative. By producing parts with minimal waste, manufacturers can achieve cost savings while also reducing their environmental footprint. This waste reduction is particularly important in industries that rely on expensive or rare materials, as it allows for more efficient use of resources.

Additionally, 3D printing enables the recycling and reuse of materials, further contributing to waste reduction. Many 3D printers are capable of using recycled plastics and other materials, allowing manufacturers to repurpose waste into new products. This closed-loop approach not only reduces the need for virgin materials but also supports circular economy principles, where waste is minimized, and resources are continuously reused.

The customization capabilities of 3D printing also play a role in reducing waste. By allowing for the production of tailored products on demand, 3D printing eliminates the need for large inventories and excess stock. This just-in-time manufacturing approach reduces the risk of overproduction and obsolescence, leading to less waste and a more efficient use of resources.

Energy Efficiency in 3D Printing Processes

Energy efficiency is a crucial aspect of sustainable manufacturing, and 3D printing offers several advantages in this regard. Traditional manufacturing processes often involve multiple steps and require significant energy inputs, from raw material extraction to final product assembly. In contrast, 3D printing streamlines production by consolidating these steps into a single process, reducing the overall energy consumption.

One of the ways 3D printing enhances energy efficiency is through its ability to produce lightweight structures. By optimizing designs for weight reduction, manufacturers can create products that require less energy to transport and use. This is particularly beneficial in industries such as aerospace and automotive, where reducing the weight of components can lead to significant fuel savings and lower emissions.

Moreover, 3D printing allows for the use of energy-efficient production techniques, such as direct energy deposition and selective laser sintering. These methods focus energy precisely where it is needed, minimizing waste and reducing the overall energy required for production. By optimizing energy usage, 3D printing contributes to more sustainable manufacturing practices.

The decentralized nature of 3D printing also supports energy efficiency by enabling localized production. By manufacturing products closer to the point of use, 3D printing reduces the energy associated with transportation and logistics. This localized approach not only decreases the carbon footprint of manufacturing but also enhances supply chain resilience and reduces reliance on fossil fuels.

Conclusion

In conclusion, the role of 3D printing in sustainable manufacturing practices is multifaceted and impactful. By offering environmental benefits such as reduced material waste, the use of sustainable materials, and localized production, 3D printing is paving the way for more eco-friendly manufacturing processes. Its ability to minimize waste through precise material usage and recycling further supports sustainable practices, while its energy-efficient production techniques contribute to reduced energy consumption. As industries continue to seek innovative solutions for sustainability, 3D printing stands out as a promising technology that can help achieve these goals. By embracing the potential of additive manufacturing, manufacturers can not only enhance their environmental performance but also drive economic growth and innovation in a rapidly evolving market.