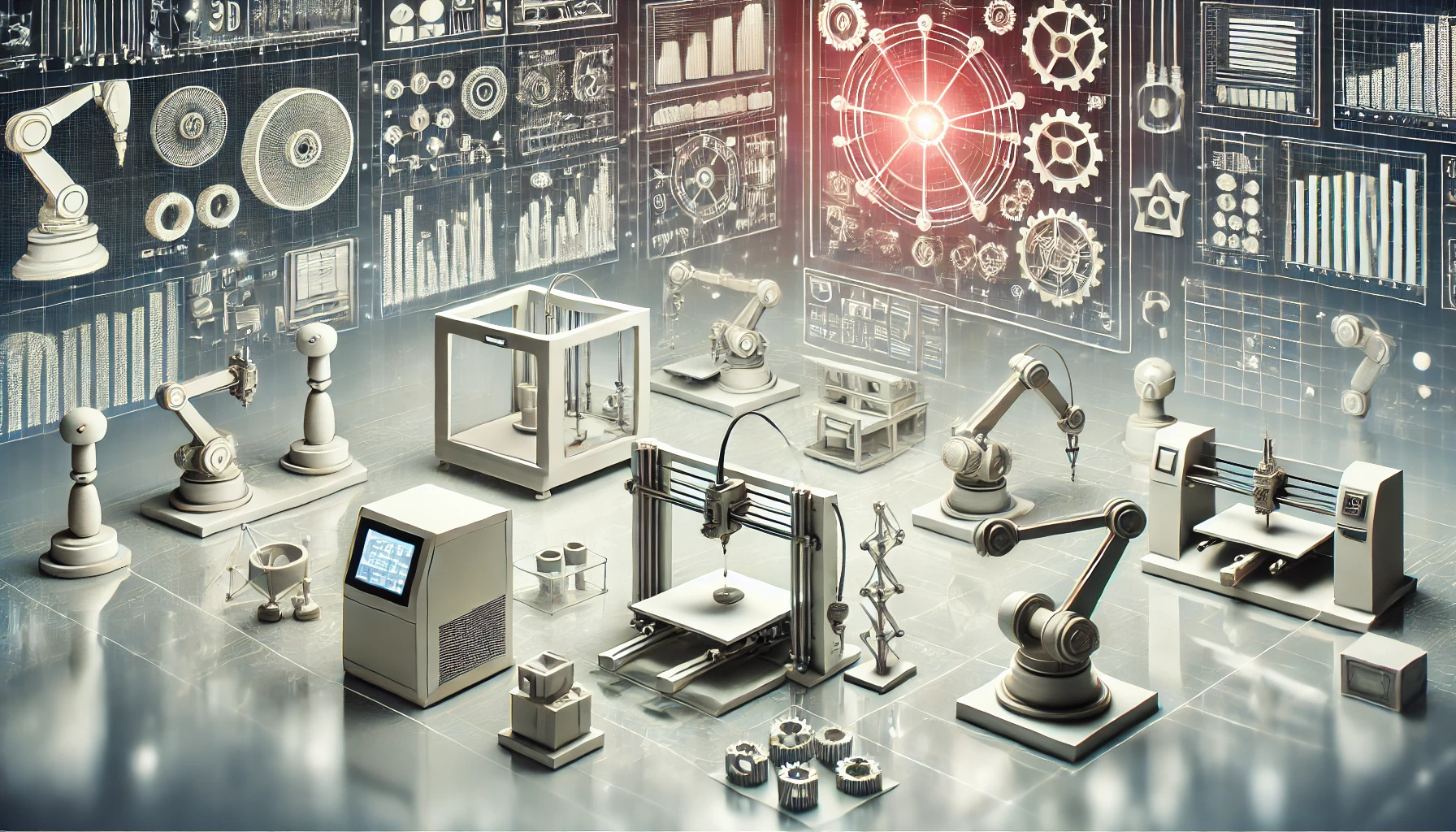

Artificial Intelligence (AI) is increasingly becoming a transformative force across various sectors, including manufacturing and technology. One of the most significant areas where AI is making a profound impact is in 3D printing, a method of additive manufacturing that creates three-dimensional objects from digital models. The integration of AI into this technology not only enhances efficiency and precision but also drives innovations that push the boundaries of what is possible. This article explores the role of AI in 3D printing, focusing on its impact on efficiency and precision and the innovative advancements it facilitates.

The Impact of AI on 3D Printing Efficiency and Precision

The integration of AI in 3D printing processes significantly enhances operational efficiency. By using predictive algorithms, manufacturers can optimize their printing schedules and minimize downtime. For instance, AI systems can analyze past production data to forecast potential bottlenecks, enabling proactive management of resources. This optimization translates into reduced production times and lower costs, making 3D printing a more viable option for various industries.

In addition to efficiency, AI technology plays a crucial role in improving the precision of 3D printed objects. Machine learning algorithms can analyze the intricacies of 3D models and adjust parameters during the printing process to ensure that every detail is replicated accurately. This capability is particularly important in sectors such as aerospace, automotive, and healthcare, where precision is critical for the functionality and safety of components. As a result, the quality of 3D printed products continues to rise, meeting the rigorous standards set by these industries.

Moreover, AI-powered quality control systems can monitor the printing process in real-time, identifying errors or deviations from the desired specifications immediately. By implementing computer vision and other AI technologies, manufacturers can ensure that products meet quality assurance benchmarks before they leave the production floor. This proactive approach to quality control not only reduces waste but also enhances the reliability of 3D printing as a manufacturing method.

Innovations in 3D Printing Driven by Artificial Intelligence

Artificial intelligence is also at the forefront of driving innovative advancements in 3D printing technology. AI algorithms can facilitate complex design processes by generating optimized structures that would be impractical for human designers to conceive. By employing generative design techniques, AI can create lightweight yet strong geometries that are tailored to specific performance criteria, allowing for the development of products that are both efficient and high-performing.

Additionally, AI is enhancing material science in 3D printing by enabling the discovery of new materials and composites that can be used in additive manufacturing. Machine learning models can analyze the properties and behaviors of different materials, predicting their performance under various conditions. This capability leads to the creation of new materials specifically designed for 3D printing, expanding the range of applications for the technology across industries such as construction, healthcare, and consumer goods.

Lastly, the use of AI in 3D printing is fostering advancements in mass customization. By leveraging AI’s data processing capabilities, manufacturers can efficiently produce customized products tailored to individual customer needs without sacrificing efficiency. As a result, businesses can offer personalized solutions at scale, meeting the growing demand for unique products in today’s market. This shift towards mass customization not only adds value to the consumer experience but also positions 3D printing as a potent competitor to traditional manufacturing methods.

In conclusion, the intersection of artificial intelligence and 3D printing technology is revolutionizing the manufacturing landscape. By enhancing efficiency and precision, AI is making additive manufacturing more effective and reliable. Additionally, the innovations driven by AI are pushing the boundaries of material science and design, enabling new possibilities that were once thought to be unattainable. As this synergy continues to evolve, it is likely that the role of AI in 3D printing will expand further, leading to transformative changes across various industries and enhancing the potential of this groundbreaking technology.